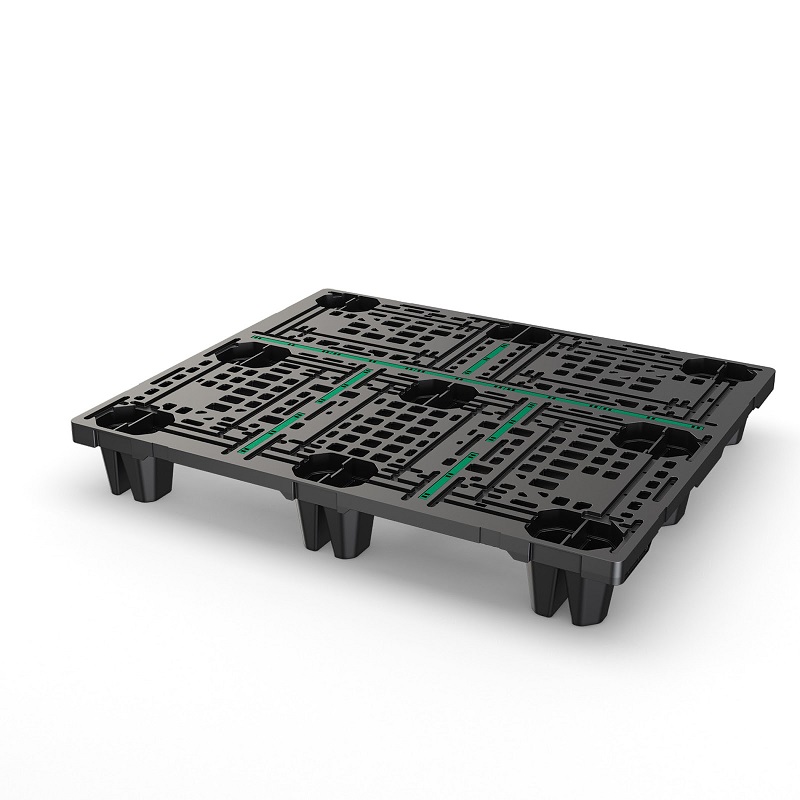

Polymer Logistics has announced a successful trial for it Cleanpal plastic pallet for the fresh produce supply chain. D.E. Brand, the supplier of quality Brassica vegetables, and the leading retailer ASDA participated together in the project, where the new pallets were used for field palletisation and shipment to ASDA’s central distribution centres in Skelmersdale and Lutterworth.

The trial’s purpose was to prove the efficacy of Cleanpal for the palletisation and seamless shipment of fresh produce. As the fresh produce supply chain continues to evolve, it is becoming more challenging to transport fresh produce in wood pallets. Issues such as water absorption, frequent damage, inconsistent weight, exposed nails, and splinters bring further issues associated with it, including hygiene and handling.

“In today’s supply chain, speed, safety and reliable quality have become essential. Problems related to the use of wood pallets are increasingly coming under the microscope as retailers look to take their operations to the next level. This trial demonstrates how Cleanpal delivers in every category to improve the fresh produce experience,” said Adrian Dale, Managing Director at Polymer Logistics.

The project looked into a few factors, such as ease of forklift handling during loading and unloading, suitability for manual handling, and load stability in conjunction with plastic crates. Material handlers were able to experience how the plastic pallets that only weight 15kg each, can be easily lifted and stacked manually, as well as nested when they get empty to optimise the space utilisation.

CleanPal proved to be a success in all regards, with harvest workers enjoying the ease of pallet handling in the field and operators appreciating the easy fork entry, with the free underdeck providing a larger opening than found in wood pallets. No shifting or loss of palletised product was recorded, as load stability was enhanced by the use of interlocking trays. Forklift handling and pump truck manoeuvring was also easily accomplished.