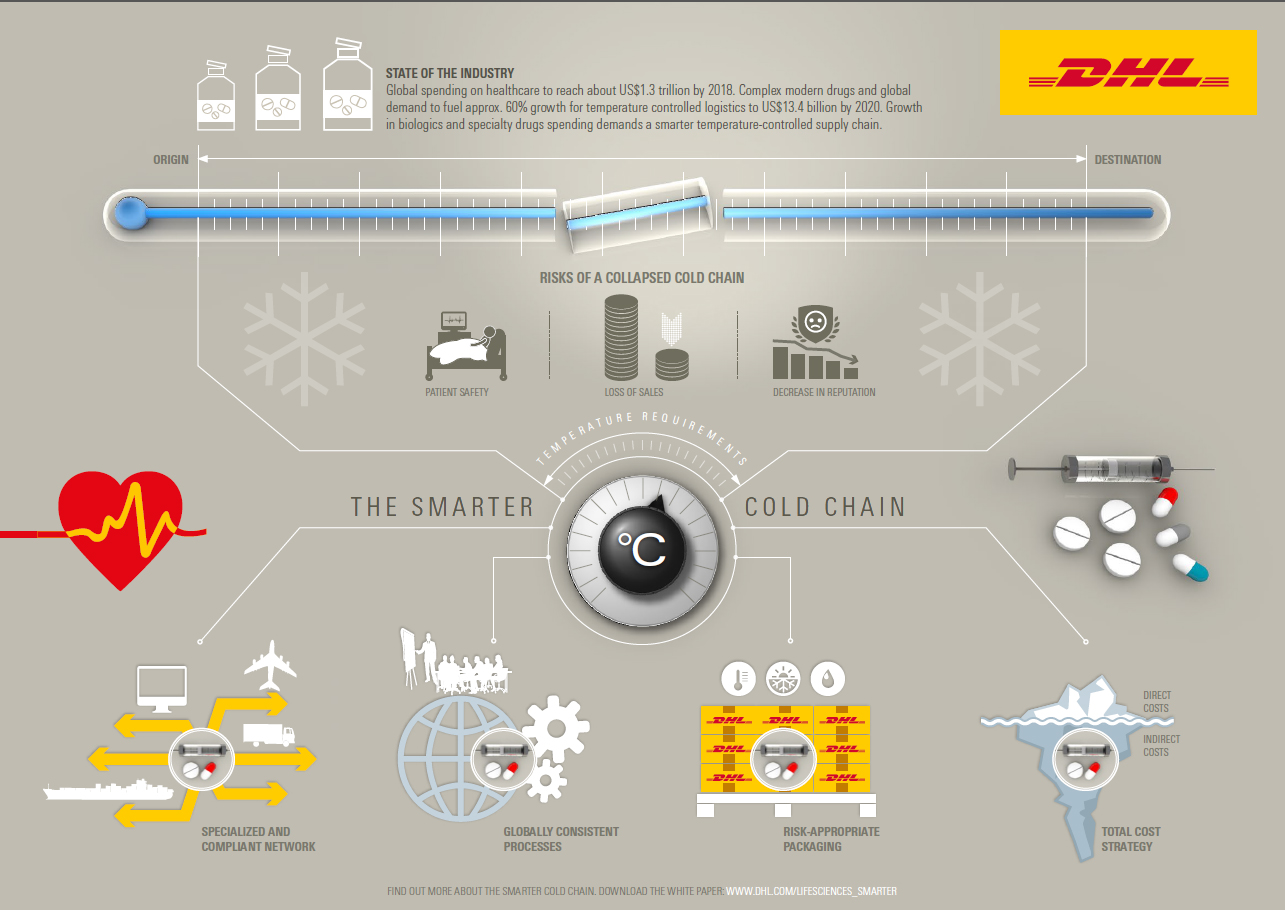

A new white paper commissioned by DHL, the world’s leading logistics company, examines how changes in the European healthcare market are impacting supply chain models. The report, ‘Adding value and reducing costs: Transforming the European medical device supply chain,’ explains what modifications medical device supply chains must undergo in order to survive in today’s new healthcare environment and ensure first-class service for patient care.

The European medical device industry is weathering a perfect storm which is shifting the business paradigm. Value-based healthcare, cost and margin pressures, and increasing regulatory and compliance requirements characterize modern European healthcare operations. These dynamics are forcing manufacturers to reevaluate their supply chain operations to remain competitive, and continue supporting healthcare providers by putting their patients first.

“The pressures facing the European medical device industry are not new: what’s changing is their intensity and momentum,” states Susanne Amholt, DHL Supply Chain’s Vice President for Business Development, Life Sciences and Healthcare, Europe. “We understand the regulatory and quality assurance environment which is rapidly adding new layers of complexity and cost to the medical device supply chain at a time when pressure to cut costs – from governments, payers, healthcare providers and patients – has never been greater. Meanwhile, there are significant differences in markets and operations.

“Illness patterns in the emerging Eastern European markets are starting to match those in the mature Western European countries, but product preferences, payer mechanisms, regulations and distribution channels continue to differ widely by country. These practices vary country-by-country, making Europe a very complex market to serve,” continues Amholt.

The white paper discusses: the current state of the market; how trends impact the European medical device supply chain; and what new supply chain strategies, practices and solutions are available to address these developments. Outlined in the white paper are four important strategies that medical device and life science companies can implement to address these changes:

- Segmenting supply chains by product value: Segmentation includes tailoring the mode of transportation and warehousing and the distribution channels in each country, according to the type and category of medical device. Low-value, high-volume consumer medical devices may be transported by ocean, long-haul road freight and faster, higher cost modes for ’emergency’ situations. From a network perspective, these same products may be distributed via regional distribution centers or cross-dock facilities located in closer proximity to the end market.

- Creating a direct to customer channel: To reduce costs and increase profits, manufacturers are beginning to look at serving certain customers direct. This approach provides an alternative to the traditional distributor-intermediary model and connects businesses more directly with patients. However, the decision of going direct versus through a distributer is highly reliant on several factors, including attributes such as cost of product, security needs and number of final distribution points.

- Leveraging shared-use distribution centers: Under a shared services solution, multiple manufacturers house their product with a single third party logistics service provider (3PL) in a shared network of facilities and transportation capacity, which streamlines the supply chain for manufacturers and their customers.

- Outsourcing logistics to a third party: Outsourcing the logistics activities and operations to a 3PL with expertise in managing medical device supply chains frees up the manufacturer to focus on its core business – developing and producing medical devices. It enhances flexibility by tapping into the capabilities portfolio, infrastructure and expertise of a global 3PL – rather than trying to build and maintain those assets and processes in-house.

The ‘Adding value and reducing costs’ white paper was prepared by Lisa Harrington, President of the lharrington group LLC, who said, “The time has come to re-think the European medical device operating model in general and the supply chain in particular. Leading manufacturers are doing just that. They are working with their logistics service providers to reengineer their supply chains to embrace outsourcing solutions, shared services and other supply chain solutions. Meeting the twin challenges of reducing costs and delivering on service commitments is not an easy task. However, with the right partnerships, it can be done in a manner where everyone wins, including the ultimate customer – the patient.”