Daimler Trucks North America, or DTNA, has announced that they will be making their first delivery of plastic parts which have been made through 3D printing to customers in the next few weeks. DTNA has said that the development programme that has got them to this point has been looking into the use of 3D printed parts in order to better serve their customers. It is thought that the technology adopted will help to supply those in need of parts in circumstances where supply would be difficult in the traditional supply chain models. For example, this process will help with the supply of parts for older truck models components that have low or intermittent demand.

The company have commented that they are confident the adoption of this new technology when supplying customers with parts will soon play a significant role in the manufacturing industry. Jay Johnson is the General Manager of the Aftermarket Supply Chain at DTNA and has said that the move is a part of the company’s larger plans to modernise their services and lead the market by offering the greatest availability of parts. The company has also added three new parts distribution centres as well as a dedicated delivery service which will help to put the DTNA on the path to achieving their long term goals.

During the pilot phase of this service, DTNA has planned to release controlled numbers of the 3D printed products and then offer an opportunity for their customers and technicians to give feedback on the products they have received. The company will also be working to collect performance data and looking into the potential to using this technology for meeting future demand.

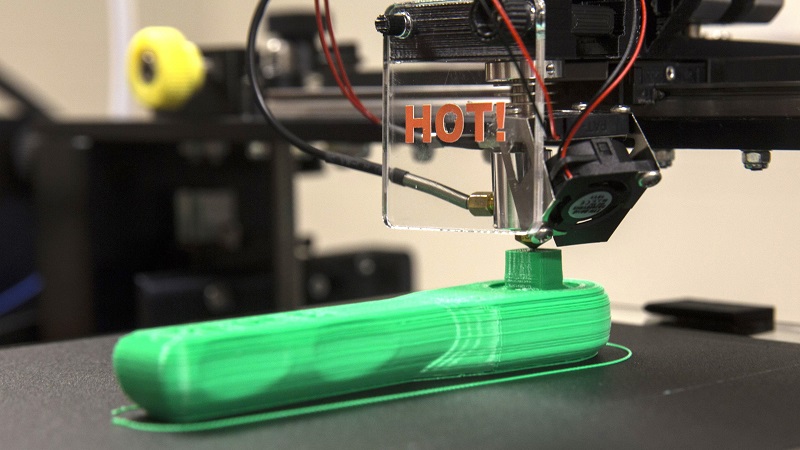

In order to print vehicle parts, DTNA partnered with a 3D printing service firm, The Technology House in order to produce the parts needed by using Selective Laser Sintering, a process which sees the part built up layer by layer using powdered plastic and a high powered laser.